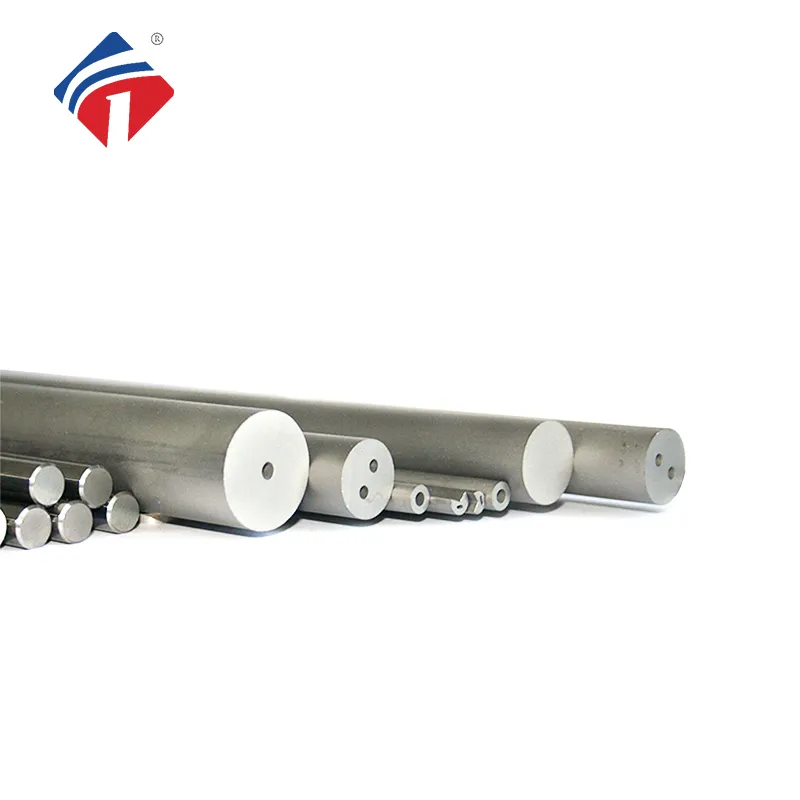

paglalarawan

tygk encoding system

|

kategorya ng ①production |

②tygk grade |

③type classfication |

④shape code |

⑤diameter |

⑥lengh |

|

h0-unround |

25u-ty25uf |

br-rods |

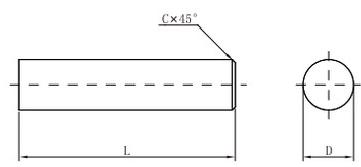

1-walang chamfer |

|

|

|

h1-half-ground |

25s-ty25s |

bq-ball-nose endmill blank |

2-chamfer |

|

|

|

h2-ground h6 |

20-ty20 |

bt step-rods |

3-double chamfer |

|

|

|

h7-ground h7 |

05a-ty05a |

|

|

|

|

|

|

10u-ty10uf |

|

|

|

|

panimula ng grade

|

grado |

iso grade grade |

grasiz (µm) |

nilalaman ng kobal (%) |

hardnes (hra) |

density (g/cm³)

|

trs (n/m²) |

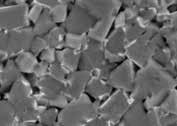

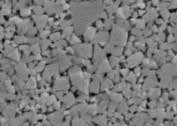

microstructure 10000x |

|

ty05a |

k15 |

1.0 |

6.0 |

92.5 |

14.95 |

2450 |

|

|

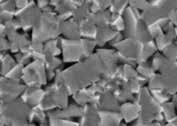

ty10uf |

k05-k10 |

0.4 |

6.0 |

94.0 |

14.80 |

3800 |

|

|

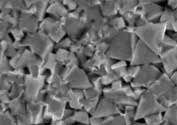

ty20 |

k20-k40 |

0.6 |

10.0 |

91.8 |

14.45 |

3800 |

|

|

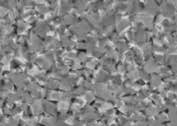

ty25s |

k20-k40 |

0.5 |

11.0 |

92.4 |

14.25 |

4000 |

|

|

ty25uf |

k20-k40 |

0.4 |

12.0 |

92.5 |

14.10 |

4200 |

|

|

|

ty10uf |

ty25s |

ty25uf |

ty20 |

ty05a |

|

|

uri ng mga tool ng pag -iwas |

inirerekumendang grado (angkop: △) |

|||||

|

endmill |

|

△ |

△ |

△ |

△ |

|

|

drills |

△ |

△ |

△ |

△ |

△ |

|

|

reamer |

|

△ |

△ |

△ |

|

|

|

materyal sa trabaho |

inirerekumendang grado (◎: pinakamahusay; ο: angkop) |

|||||

|

|

non alloy steel |

Ο |

◎ |

◎ |

◎ |

|

|

p |

mababang haluang metal na bakal |

|

Ο |

Ο |

|

◎ |

|

|

mataas na haluang metal na bakal |

|

◎ |

◎ |

◎ |

|

|

m |

hindi kinakalawang na asero |

Ο |

|

◎ |

|

|

|

|

grey cast iron |

Ο |

◎ |

Ο |

◎ |

◎ |

|

k |

ductile cast iron |

|

|

Ο |

◎ |

|

|

|

spheroidal grapayt iron |

◎ |

◎ |

Ο |

Ο |

Ο |

|

n |

aluminyo haluang metal |

|

Ο |

Ο |

◎ |

Ο |

|

copperalloy |

|

◎ |

◎ |

◎ |

Ο |

|

|

s |

nickel alloy |

|

|

◎ |

◎ |

◎ |

|

titanium alloy |

|

◎ |

◎ |

◎ |

◎ |

|

|

h |

matigas na bakal |

|

|

◎ |

Ο |

◎ |

|

iba |

kahoy |

|

Ο |

Ο |

Ο |

Ο |

|

fiber glass reinforced plastics |

|

◎ |

◎ |

|

◎ |

|

|

composite |

|

◎ |

◎ |

Ο |

Ο |

|

ty25s: inirerekomenda ang endmil 、 reamers at gravers.excllent na pagganap para sa mataas na bilis ng pagputol. angkop para sa pagputol ng matigas na bakal, aluminyo haluang metal at titanium alloy.

ty20: inirerekomenda ang drill at endminlls.

ty05a: ang drill 、 endmil at burr ay inirerekomenda.suitable para sa pagputol ng hindi mas malalim na metal, aluminyo, tanso at grapayt (patong na kinakailangan)

ang rekomendasyong grade na ito ay para lamang sa iyong sanggunian, dahil sa hugis ng mga tool sa pagputol at ang patong ay parehong may malaking impluwensya sa pagganap ng tool ng pagputol. mangyaring pumunta sa specialty ng grade para sa karagdagang impormasyon upang matulungan ang iyong pagpipilian sa grado.

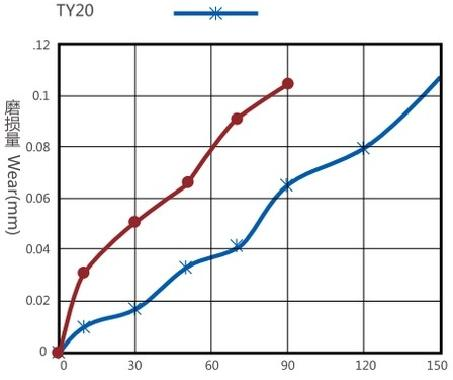

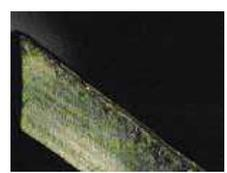

kaso ng ty20

milling die steel (40hrc)

|

|

trabaho ng piraso ng piraso |

uri ng tool |

grado |

||

|

nagtatrabaho mga kondisyon |

die steel skd61 (40hrc) |

endmill |

ty20 |

||

|

mill dia. (mm) |

haba ng plauta (mm) |

bilang ng mga plauta (n) |

patong |

paglamig |

|

|

8 |

20 |

4 |

alcrn |

natutunaw ang tubig |

|

mga kondisyon ng pagputol:

vc = 95m/min

fz = 840mm/min ae = 0.8mm

ap = 8mm

buhay +60%

haba ng pagputol (m)

kumpetisyon o kumpanya

kumpetisyon o kumpanya ty20

ty20

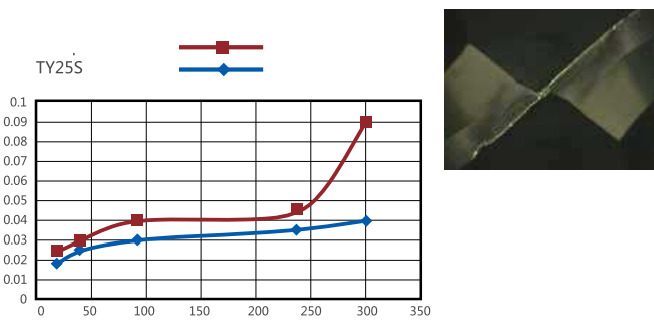

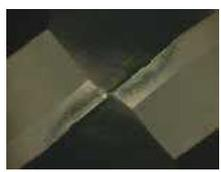

kaso ng ty25s

milling die steel (55hrc)

|

|

trabaho ng piraso ng piraso |

uri ng tool |

grado |

||

|

nagtatrabaho mga kondisyon |

die steel skd61 (55hrc) |

endmill |

ty25s |

||

|

mill dia. (mm) |

haba ng plauta (mm) |

bilang ng mga plauta (n) |

patong |

paglamig |

|

|

6 |

- |

2 |

tiain |

mist oil |

|

mga kondisyon ng pagputol:

vc = 254m/min

fz = 4200mm/min ae = 0.2mm

ap = 2mm

buhay +60%

pagputol ng haba (m) kumpetisyon m kumpanya

ty25s

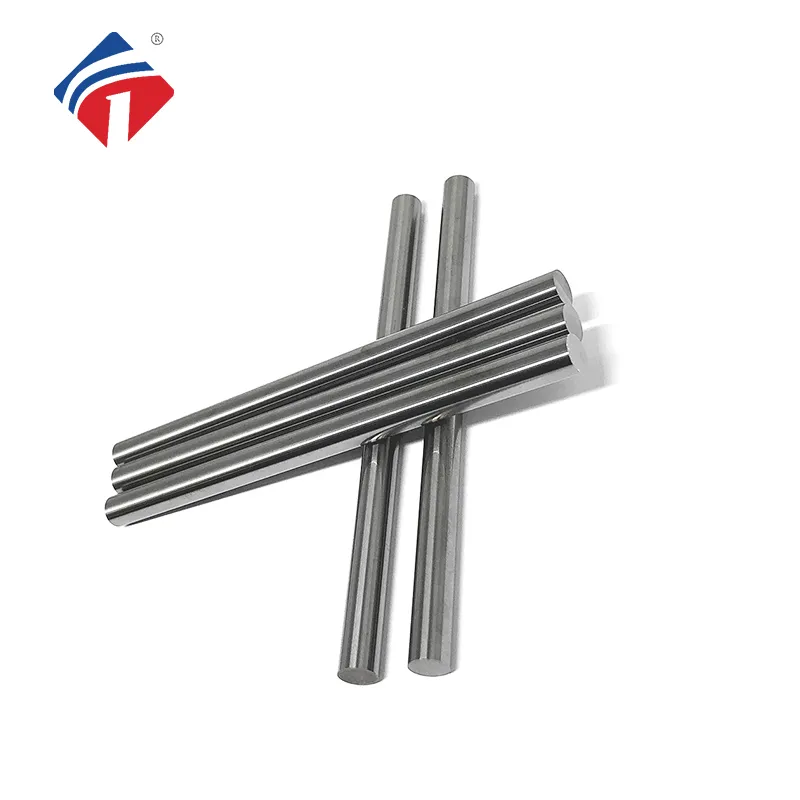

mga ground rod na may chamfer

mga ground rod na may chamfer -inch

|

kategorya ng tygkproduction h2/h7 iso h6/h5 |

||||

|

pagtukoy |

sukat |

tol.of od |

||

|

od |

l |

h6 |

h5 |

|

|

br2031038 |

1/8 |

1/2 |

√ |

√ |

|

br2031050 |

1/8 |

2 |

√ |

√ |

|

br2031063 |

1/8 |

2-1/2 |

√ |

√ |

|

br2031076 |

1/8 |

3 |

√ |

√ |

|

br2047050 |

3/16 |

2 |

√ |

√ |

|

br2047076 |

3/16 |

3 |

√ |

√ |

|

br2063050 |

1/4 |

2 |

√ |

√ |

|

br2063063 |

1/4 |

2-1/2 |

√ |

√ |

|

br2063076 |

1/4 |

3 |

√ |

√ |

|

br2063101 |

1/4 |

4 |

√ |

√ |

|

br2079063 |

5/16 |

2-1/2 |

√ |

√ |

|

br2050100 |

5.0 |

100 |

√ |

√ |

|

br2050150 |

5.0 |

150 |

√ |

√ |

|

br2060050 |

6.0 |

50 |

√ |

√ |

|

br2060060 |

6.0 |

60 |

√ |

√ |

|

br2060075 |

6.0 |

75 |

√ |

√ |

|

br2060100 |

6.0 |

100 |

√ |

√ |

|

br2060150 |

6.0 |

150 |

√ |

√ |

|

br2070055 |

7.0 |

55 |

√ |

√ |

|

br2070060 |

7.0 |

60 |

√ |

√ |

|

br2080060 |

8.0 |

60 |

√ |

√ |

|

br2080075 |

8.0 |

75 |

√ |

√ |

|

br2080080 |

8.0 |

80 |

√ |

√ |

|

br2080090 |

8.0 |

90 |

√ |

√ |

|

br2080100 |

8.0 |

100 |

√ |

√ |

|

br2080150 |

8.0 |

150 |

√ |

√ |

|

br2100070 |

10.0 |

70 |

√ |

√ |

|

br2100075 |

10.0 |

75 |

√ |

√ |

|

br2100090 |

10.0 |

90 |

√ |

√ |

|

br2100100 |

10.0 |

100 |

√ |

√ |

|

br2100125 |

10.0 |

125 |

√ |

√ |

|

br2120110 |

11.0 |

110 |

√ |

√ |

|

br2120075 |

12.0 |

75 |

√ |

√ |

|

br2120090 |

12.0 |

90 |

√ |

√ |

|

br2120100 |

12.0 |

100 |

√ |

√ |

|

br2120120 |

12.0 |

120 |

√ |

√ |

|

br2140075 |

14.0 |

75 |

√ |

√ |

|

br2140110 |

14.0 |

110 |

√ |

√ |

|

br2140125 |

14.0 |

125 |

√ |

√ |

|

br2160100 |

16.0 |

100 |

√ |

√ |

|

br2160125 |

16.0 |

125 |

√ |

√ |

|

br2180100 |

18.0 |

100 |

√ |

√ |

|

br2180150 |

18.0 |

150 |

√ |

√ |

|

br2200100 |

20.0 |

100 |

√ |

√ |

|

br2200120 |

20.0 |

120 |

√ |

√ |

|

br2200150 |

20.0 |

150 |

√ |

√ |

|

br2250100 |

25.0 |

100 |

√ |

√ |

|

br2250150 |

25.0 |

150 |

√ |

√ |

|

|

|

|

|

|

|

|

diameter d, pulgada |

chamfer c, pulgada |

||

|

(saklaw) |

(tol.) |

(saklaw) |

(tol.) |

|

|

1/8≤0ds1 |

h5, h6 |

1/8s0d <7/16 |

+.015±.004 |

|

|

|

|

7/16sods1 |

+.031±.008 |

|

|

haba l, pulgada |

anggulo, degree |

|||

|

(saklaw) |

(tol.) |

(saklaw) |

(tol.) |

|

|

1/2≤ls3/4 |

+1/16,-0 |

1/8sod≤1 |

45°±3° |

|

(1) br2 thecode para sa serye na may chamfer ay br2

(2) br1 ang code forseries na walang chamfer ay br1

(3) br3 ang code para sa serye na may mga chamfers ay br3

unit (pulgada)

pag -order ng halimbawa:

(ang uri ay para sa pag -order ngexample, na ang ilalim ay orange.)

|

nag -order ng mesa |

||||||

|

hindi. |

grado |

uri ng pag -order |

kategorya at uri ng produksiyon |

tol. |

halaga |

pansinin |

|

1 |

ty20 |

h2-br2031038 |

tygk |

5000 |

|

|

|

2 |

|

|

|

|

|

|

tandaan : ito ay dadalhin bilang pamantayang tygk, kung walang pag -aasawa na isoffered.

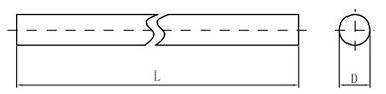

undourgure rods

undourgure rods -inch

|

tygk production category ho: blanks |

||

|

pagtukoy |

sukat |

|

|

od |

l |

|

|

br1031333 |

1/8 |

13-1/8 |

|

br1035333 |

9/64 |

13-1/8 |

|

br1039333 |

5/32 |

13-1/8 |

|

br1043333 |

11/64 |

13-1/8 |

|

br1047333 |

3/16 |

13-1/8 |

|

br1051333 |

13/64 |

13-1/8 |

|

br1055333 |

7/32 |

13-1/8 |

|

br1059333 |

15/64 |

13-1/8 |

|

br1063333 |

1/4 |

13-1/8 |

|

br1071307 |

9/32 |

12-1/8 |

|

br1075307 |

19/64 |

12-1/8 |

|

br1079307 |

5/16 |

12-1/8 |

|

br1083307 |

21/64 |

12-1/8 |

|

br1087307 |

11/32 |

12-1/8 |

|

br1091307 |

23/64 |

12-1/8 |

|

br1095307 |

3/8 |

12-1/8 |

|

br1099307 |

25/64 |

12-1/8 |

|

br1103307 |

13/32 |

12-1/8 |

|

br1107307 |

27/64 |

12-1/8 |

|

br1111307 |

7/16 |

12-1/8 |

|

br1115307 |

29/64 |

12-1/8 |

|

br1119307 |

15/32 |

12-1/8 |

|

br1123307 |

31/64 |

12-1/8 |

|

br1127307 |

1/2 |

12-1/8 |

|

br1134307 |

17/32 |

12-1/8 |

|

br1142307 |

9/16 |

12-1/8 |

|

br1158307 |

5/8 |

12-1/8 |

|

br1174307 |

11/16 |

12-1/8 |

|

br1190307 |

3/4 |

12-1/8 |

|

br1206307 |

13/16 |

12-1/8 |

|

br1222307 |

7/8 |

12-1/8 |

|

br1238307 |

15/16 |

12-1/8 |

|

br1254307 |

1 |

12-1/8 |

|

br1020330 |

2.0 |

330 |

|

br1025330 |

2.5 |

330 |

|

br1030330 |

3.0 |

330 |

|

br1035330 |

3.5 |

330 |

|

br1040330 |

4.0 |

330 |

|

br1045330 |

4.5 |

330 |

|

br1050330 |

5.0 |

330 |

|

br1060330 |

6.0 |

330 |

|

br1065330 |

6.5 |

330 |

|

br1070330 |

7.0 |

330 |

|

br1075330 |

7.5 |

330 |

|

br1080330 |

8.0 |

330 |

|

br1085330 |

8.5 |

330 |

|

br1090330 |

9.0 |

330 |

|

br1095330 |

9.5 |

330 |

|

br1100330 |

10.0 |

330 |

|

br1105330 |

10.5 |

330 |

|

br1110330 |

11.0 |

330 |

|

br1115330 |

11.5 |

330 |

|

br1120330 |

12.0 |

330 |

|

br1125330 |

12.5 |

330 |

|

br1130330 |

13.0 |

330 |

|

br1135330 |

13.5 |

330 |

|

br1140330 |

14.0 |

330 |

|

br1145330 |

14.5 |

330 |

|

br1150330 |

15.0 |

330 |

|

br1155330 |

15.5 |

330 |

|

br1160330 |

16.0 |

330 |

|

br1165330 |

16.5 |

330 |

|

br1170330 |

17.0 |

330 |

|

br1175330 |

17.5 |

330 |

|

br1180330 |

18.0 |

330 |

|

br1185330 |

18.5 |

330 |

|

br1190330 |

19.0 |

330 |

|

br1195330 |

19.5 |

330 |

|

br1200330 |

20.0 |

330 |

|

br1205330 |

20.5 |

330 |

|

br1210330 |

21.0 |

330 |

|

br1215330 |

21.5 |

330 |

|

br1220330 |

22.0 |

330 |

|

br1225330 |

22.5 |

330 |

|

br1230330 |

23.0 |

330 |

|

br1235330 |

23.5 |

330 |

|

br1240330 |

24.0 |

330 |

|

br1245330 |

24.5 |

330 |

|

br1250330 |

25.0 |

330 |

|

br1255330 |

25.5 |

330 |

|

br1260330 |

26.0 |

330 |

|

br1265330 |

26.5 |

330 |

|

br1270330 |

27.0 |

330 |

|

br1275330 |

27.5 |

330 |

|

br1280330 |

28.0 |

330 |

|

br1285330 |

28.5 |

330 |

|

br1290330 |

29.0 |

330 |

|

br1300330 |

30.0 |

330 |

|

br1305330 |

30.5 |

330 |

|

br1310330 |

31.0 |

330 |

|

br1315330 |

31.5 |

330 |

|

br1320330 |

32.0 |

330 |

|

br1325330 |

32.5 |

330 |

|

br1330330 |

33.0 |

330 |

|

br1335330 |

33.5 |

330 |

|

br1340330 |

34.0 |

330 |

|

br1345330 |

34.5 |

330 |

|

br1350330 |

35.0 |

330 |

|

br1355330 |

35.5 |

330 |

|

br1360330 |

36.0 |

330 |

|

br1365330 |

36.5 |

330 |

|

br1370330 |

37.0 |

330 |

|

br1375330 |

37.5 |

330 |

|

br1380330 |

38.0 |

330 |

|

br1385330 |

38.5 |

330 |

|

br1390330 |

39.0 |

330 |

|

br1400330 |

40.0 |

330 |

|

br1405330 |

40.5 |

330 |

|

br1410330 |

41.0 |

330 |

|

br1415330 |

41.5 |

330 |

|

br1420330 |

42.0 |

330 |

|

pamantayan |

diameter d, mm |

|

|

saklaw |

tol. |

|

|

2≤0d <3 |

+0.15~+0.30 |

|

|

3≤od≤6 |

+0.30~+0.50 |

|

|

6 |

+0.30~+0.60 |

|

|

12 |

+0.30~+0.70 |

|

|

16 |

+0.30~+0.80 |

|

|

haba l, mm |

||

|

saklaw |

tol. |

|

|

330 |

+5,-0 |

|

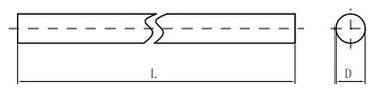

ground rod

pulgada

|

iso h6/h5 tygk production category h2/h7 |

||

|

pagtukoy |

sukat |

|

|

od |

l |

|

|

br1063307 |

1/4 |

12-1/2 |

|

br1071307 |

9/32 |

12-1/2 |

|

br1075307 |

19/64 |

12-1/2 |

|

br1079307 |

5/16 |

12-1/2 |

|

br1083307 |

21/64 |

12-1/2 |

|

br1087307 |

11/32 |

12-1/2 |

|

br1091307 |

23/64 |

12-1/2 |

|

br1095307 |

3/8 |

12-1/2 |

|

br1099307 |

25/64 |

12-1/2 |

|

br1103307 |

13/32 |

12-1/2 |

|

br1107307 |

27/64 |

12-1/2 |

|

br1111307 |

7/16 |

12-1/2 |

|

br1115307 |

29/64 |

12-1/2 |

|

br1119307 |

15/32 |

12-1/2 |

|

br1123307 |

31/64 |

12-1/2 |

|

br1127307 |

1/2 |

12-1/2 |

|

br1134307 |

17/32 |

12-1/2 |

|

br1142307 |

9/16 |

12-1/2 |

|

br1158307 |

5/8 |

12-1/2 |

|

br1174307 |

11/16 |

12-1/2 |

|

br1190307 |

3/4 |

12-1/2 |

|

br1206307 |

13/16 |

12-1/2 |

|

br1222307 |

7/8 |

12-1/2 |

|

br1238307 |

15/16 |

12-1/2 |

|

br1254307 |

1 |

12-1/2 |

|

br1060330 |

6 |

330 |

|

br1070330 |

7 |

330 |

|

br1080330 |

8 |

330 |

|

br1090330 |

9 |

330 |

|

br1100330 |

10 |

330 |

|

br1110330 |

11 |

330 |

|

br1120330 |

12 |

330 |

|

br1130330 |

13 |

330 |

|

br1140330 |

14 |

330 |

|

br1150330 |

15 |

330 |

|

br1160330 |

16 |

330 |

|

br1170330 |

17 |

330 |

|

br1180330 |

18 |

330 |

|

br1190330 |

19 |

330 |

|

br1200330 |

20 |

330 |

|

br1210330 |

21 |

330 |

|

br1220330 |

22 |

330 |

|

br1230330 |

23 |

330 |

|

br1240330 |

24 |

330 |

|

br1250330 |

25 |

330 |

|

br1260330 |

26 |

330 |

|

br1270330 |

27 |

330 |

|

br1280330 |

28 |

330 |

|

br1290330 |

29 |

330 |

|

br1300330 |

30 |

330 |

|

br1310330 |

31 |

330 |

|

br1320330 |

32 |

330 |

|

br1330330 |

33 |

330 |

|

br1340330 |

34 |

330 |

|

br1350330 |

35 |

330 |

|

br1360330 |

36 |

330 |

|

br1370330 |

37 |

330 |

|

br1380330 |

38 |

330 |

|

br1390330 |

39 |

330 |

|

br1400330 |

40 |

330 |

|

br1410330 |

41 |

330 |

|

br1420330 |

42 |

330 |

|

pamantayan |

diameter d, mm |

|

|

saklaw |

tol. |

|

|

6 |

h6, h5 |

|

|

haba lmm |

||

|

saklaw |

tol. |

|

|

330 |

+5,-0 |

|

|

i -type ang : c b t 3 0 5 kinokontrol ng microcomputer ang electronic flexural na pagsubok sa makina kawastuhan : 1n gb/t3851-1983≈iso3327-1982 astm b406-1996 |

|

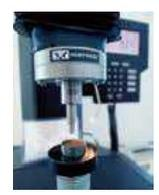

i -type ang : r b 2 0 0 0 r rockwell hardness tester usa wilson gb/t3849-1983≈iso3788/1-1982 astm b294-1992 |

|

i -type : ld j - 5800 magnetic performance meter na-import na magnetic saturation at coercivity test all-in-one machine |

|

electronic balance : xs105 ako ttler toledo katumpakan : 0.01mg gb/t3850≈iso3369 astm b294 |

|

metallographic microscope : larawan r .a2m carlzeiss gbt3479-1983≈iso4505-1978 astm b276-2005 gbt3448-1983≈iso4499-1978 astm b390-1992 |

mga instrumento sa pagsubok sa pag -aari

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de